|

Operating Principle

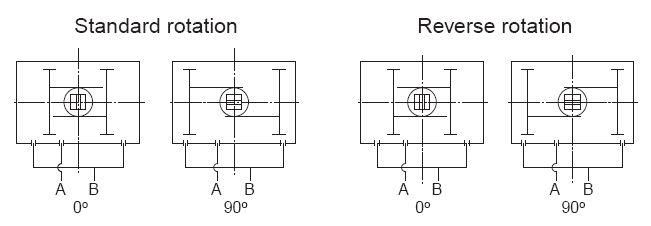

Double acting

Standard rotation:

Air to port A forces the pistons outwards, causing the pinion to turn counter clockwise while the air is being exhausted from port B. Air to port B forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from port A.

Reverse rotation:

Air to port A forces the pistons outwards, causing the pinion to turn clockwise while the air is being exhausted from port B. Air to port B forces the pistons inwards, causing the pinion to turn counter clockwise while the air is being exhausted from port A.

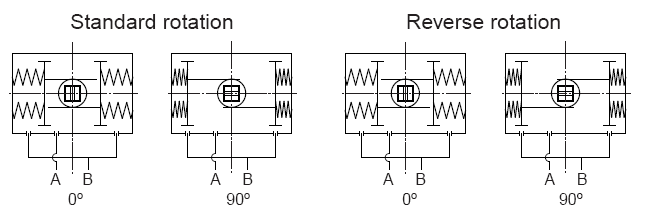

Spring return

Standard rotation:

Air to port A forces the pistons outwards, causing the springs to compress, the pinion turns counter clockwise while air is being exhausted from port B. Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

Reverse rotation:

Air to port A forces the pistons outwards, causing the springs to compress, the pinion turns clockwise while air is being exhausted from port B. Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns counter clockwise while air is being exhausted from port A.

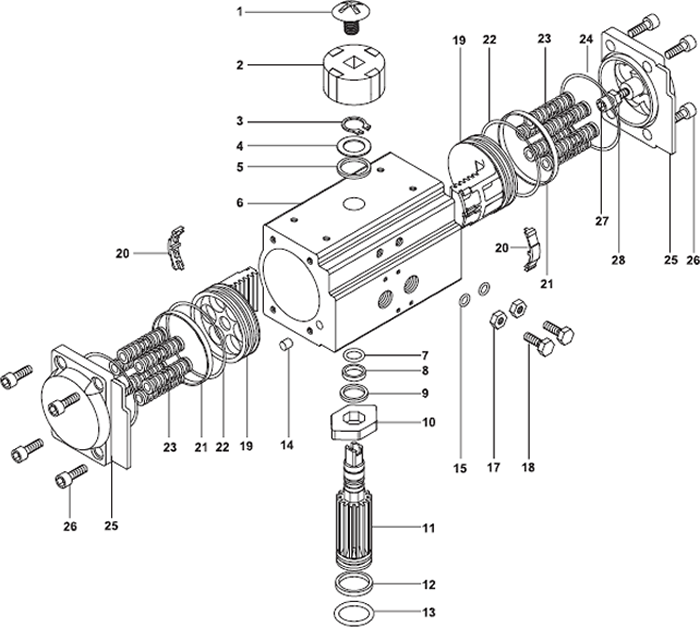

Assemble, Parts and Material

|

No. |

Description |

Qty |

Standards Material |

Protection |

Optional Material |

|

1 |

Indicator screw |

1 |

Plastic(ABS) |

|

|

|

2 |

Indicator |

1 |

Plastic(ABS) |

|

|

|

3 |

Spring clip |

1 |

Stainless steel(304) |

|

|

|

4 |

Metal washer |

1 |

Stainless steel(304) |

|

|

|

5 |

Outside washer |

1 |

polyoxymethylene |

|

|

|

6 |

Body |

1 |

Extruded aluminum alloy

(6005-T5) |

Hard anodized etc |

|

|

7 |

O-ring(pinion top) |

1 |

NBR |

|

Viton/silicone |

|

8 |

Bearing(pinion top) |

1 |

polyoxymethylene |

|

|

|

9 |

Inside washer |

1 |

polyoxymethylene |

|

|

|

10 |

Travel stop |

1 |

Alloy steel(45#) |

|

|

|

11 |

Pinion |

1 |

Alloy steel(45#) |

Nickel plated |

Stainless steel |

|

12 |

Bearing (pinion bottom) |

1 |

NBR |

|

Viton/silicone |

|

13 |

O-ring(pinion bottom) |

1 |

polyoxymethylene |

|

|

|

14 |

Hole sealant |

2 |

NBR |

|

Viton/silicone |

|

15 |

O-ring(adjust screw) |

2 |

NBR |

|

Viton/silicone |

|

17 |

Nut (adjust screw) |

2 |

Stainless steel(304) |

|

|

|

18 |

Adjust screw |

2 |

Stainless steel(304) |

|

|

|

19 |

Piston |

2 |

Die-Cast aluminum(101A) |

Anodized/zinc galvanized |

Stainless steel |

|

20 |

Plate(piston) |

2 |

polyoxymethylene |

|

|

|

21 |

Bearing (piston) |

2 |

polyoxymethylene |

|

|

|

22 |

O-ring(piston) |

2 |

NBR |

|

Viton/silicone |

|

23 |

Spring |

0~12 |

Spring steel |

Dip coating |

|

|

24 |

O-ring(end cap) |

2 |

NBR |

|

Viton/silicone |

|

25 |

End cap |

2 |

Die-Cast aluminum(ADC12) |

Powder polyester painted etc |

|

|

26 |

Cap screw |

8 |

Stainless steel(304) |

|

|

|

27 |

Stop screw |

2 |

Stainless steel(304) |

|

|

|

28 |

Nut (stop screw) |

2 |

Stainless steel(304) |

|

| |

|