|

Design

Our newly-designed K-Torc C Series Pneumatic Actuator is aluminum rack & pinion actuators in double acting and spring return based on our innovative and patented technology. This kind of actuator features a top mount multifunction indicator and open-close stop adjustment as a standard. In addition, state-of-the-art engineering has allowed us to reduce the size of the actuator without losing any torque. The features and characteristics of the actuator have kept pace with 4th generation pneumatic actuator in the world.

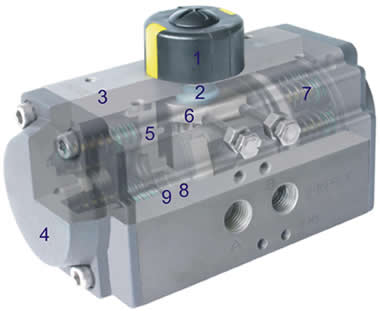

Structure

1. Indicator 1. Indicator

Position indicator with NAMUR is convenient for mounting accessories such as limit switch box, positioner and so on.

2. Pinion

The pinion is high-precision and integrative, made from nickel alloy steel, full conform to the latest standards of ISO5211,DIN3337,NAMUR.The dimensions can be customized and the stainless steel is available.

3. Actuator body

According to the different requirements, the extruded aluminum alloy ASTM6005 body can be treated with hard anodized, powder polyester painted (different colors is available such as blue, orange, yellow etc.) or PTFE or nickel plated.

4. End caps

Die-casting aluminum powder polyester painted in different colors, PTFE or nickel plated.

5. Pistons

The twin rack pistons are made from die-casting aluminum treated with hard anodized or made from cast steel with galvanization .Symmetric mounting position, long cycle life and fast operation, reversing rotation by simply inverting the pistons.

6. Travel adjustment

The two independent external travel stop adjustment bolts can adjust  5˚ at both open and close directions easily and precisely. 5˚ at both open and close directions easily and precisely.

7. High performance springs

Preloaded coating springs are made from the high quality material for resistant to corrosion and longer cycle life, which can be demounted safely and conveniently to satisfy different requirements of torque by changing quantity of springs.

8. Bearings & guides

Made from low friction, long-life compound material, to avoid the direct contact between metals. The maintenance and replacement are easy and convenient.

9. O-rings

NBR rubber o-rings provide trouble-free operation at standard temperature ranges. For high and low temperature, viton or silicone is used.

|